Проверка

Проверка

Проверка

Проверка

Проверка

Проверка

In today’s fast-paced industrial environment, efficiency and reliability are paramount. The BES05NE inductive proximity sensor has emerged as a vital tool in achieving these goals, providing precise detection capabilities that enhance automation processes across various industries. This article delves into its features, benefits, and applications.

The BES05NE inductive proximity sensor is a state-of-the-art device designed for non-contact detection of metallic objects. It operates based on the principle of electromagnetic induction, enabling it to sense the presence or absence of metal targets without physical contact. This feature not only extends the lifespan of both the sensor and the target but also reduces wear and tear on machinery.

Высокая чувствительность: The BES05NE boasts high sensitivity, allowing it to detect small metal objects at varying distances. This ensures accurate and reliable operation even in challenging environments.

Robust Design: Built to withstand harsh industrial conditions, this sensor is encased in durable material, making it resistant to dust, moisture, and vibrations. Its IP67 rating ensures protection against ingress of foreign particles.

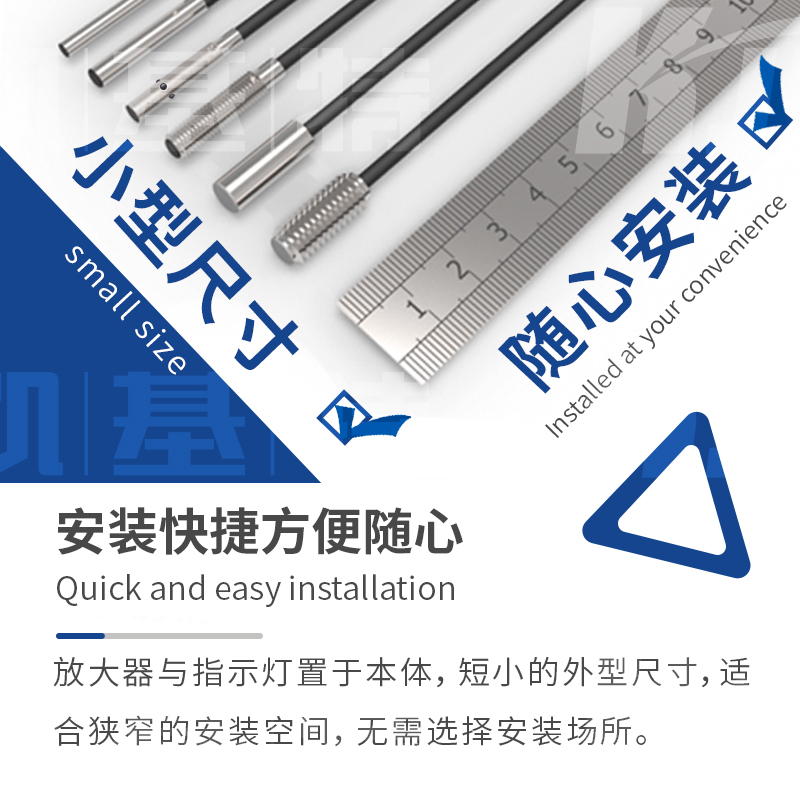

Versatile Mounting Options: With multiple mounting choices, including threaded and flat options, the BES05NE can be easily integrated into existing systems. This flexibility makes it suitable for a wide range of applications.

Extended Detection Range: Capable of detecting objects up to 10 mm away, this sensor is ideal for tasks requiring long sensing distances. Its adjustable sensitivity allows for fine-tuning to specific requirements.

The versatility of the BES05NE makes it an indispensable component in various industrial scenarios:

конвейерная система: Ensures smooth and efficient material handling by detecting the presence or absence of products on the conveyor belt, preventing bottlenecks and jams.

Робототехника: Enhances safety and accuracy in robotic operations by detecting nearby obstacles, thereby preventing collisions and improving productivity.

Производство автомобилей: Used in assembly lines for detecting components, ensuring correct placement and alignment, which is crucial for the precision required in automotive production.

Packaging Industry: Facilitates automatic packaging processes by monitoring product flow and ensuring packages are correctly sealed and labeled.

Investing in the BES05NE inductive proximity sensor offers numerous advantages for businesses aiming to optimize their operations:

Повышение эффективности: By automating detection processes, companies can significantly reduce manual intervention, leading to faster cycle times and enhanced productivity.

Improved Safety: Non-contact detection minimizes the risk of accidents and equipment damage, creating a safer working environment.

Экономия средств: The durability and reliability of the BES05NE translate to fewer replacements and maintenance costs over time, offering a great return on investment.

The BES05NE inductive proximity sensor stands out as a robust, versatile, and highly sensitive solution for industries seeking to boost their automation processes. With its ability to enhance efficiency, safety, and cost-effectiveness, it is a valuable asset for any modern industrial setup. As technology continues to advance, sensors like the BES05NE will undoubtedly play a critical role in shaping the future of industrial automation.