Проверка

Проверка

Проверка

Проверка

Проверка

Проверка

In the intricate world of industrial automation, precision and reliability are non-negotiable. Among the myriad components that ensure seamless operations, the light limit switch stands out as a critical guardian of safety and efficiency. This device, often operating behind the scenes, plays a pivotal role in controlling machinery movement, preventing over-travel, and safeguarding both equipment and personnel. Unlike traditional mechanical limit switches that rely on physical contact, modern light limit switches utilize photoelectric sensing technology to detect the presence or absence of an object within a specified range. This non-contact method offers significant advantages, including reduced wear and tear, higher operational speeds, and enhanced durability in harsh environments.

The core principle of a light limit switch involves a light emitter and a receiver. The emitter projects a beam of light—often infrared, laser, or visible LED—towards the receiver. When an object interrupts this beam, the switch triggers a signal to the control system, initiating a predefined action such as stopping a motor, reversing direction, or activating an alarm. This simple yet effective mechanism is fundamental in applications ranging from conveyor belt systems and robotic arms to packaging machinery and elevator controls. The absence of physical contact means there is no mechanical fatigue, leading to a longer service life and minimal maintenance requirements, which directly translates to lower operational costs and reduced downtime.

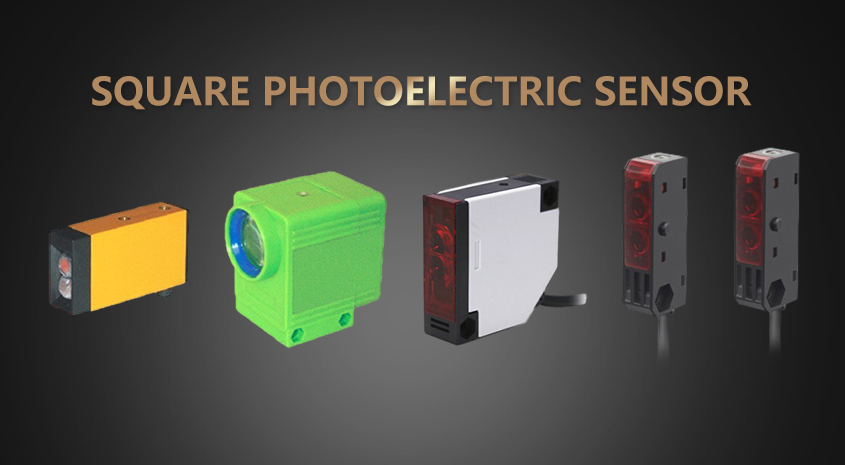

One of the standout features of contemporary light limit switches is their adaptability. They can be configured for various sensing modes, including through-beam, retro-reflective, and diffuse reflection. Through-beam models, with separate emitter and receiver units, offer the longest sensing distances and highest accuracy, ideal for large-scale industrial setups. Retro-reflective types use a single unit and a reflector, providing a practical balance of range and ease of installation. Diffuse reflection sensors detect objects by measuring the light reflected directly from the target, perfect for close-range applications where space is limited. This versatility allows engineers to select the optimal model for specific environmental conditions, whether dealing with dust, moisture, extreme temperatures, or intense vibration.

Integration into modern Industrial Internet of Things (IIoT) frameworks further amplifies the value of light limit switches. Equipped with smart connectivity options, these devices can transmit real-time operational data to centralized monitoring systems. This enables predictive maintenance, as trends in performance can be analyzed to foresee potential failures before they occur. For instance, a gradual decrease in received light intensity might indicate lens contamination, prompting an automated cleaning alert. This proactive approach shifts maintenance from a reactive, schedule-based model to a condition-based strategy, maximizing productivity and resource allocation.

Safety remains the paramount concern in any industrial setting. Light limit switches are integral to safety interlock systems, ensuring that access doors to hazardous areas are securely closed before machinery activates. They form a key part of light curtains and safety barriers, creating invisible protective fields around dangerous zones. If a beam is broken, indicating an intrusion, the system can instantly halt operations, preventing accidents. This application is crucial in industries like automotive manufacturing, metal stamping, and material handling, where worker protection is a top priority. The reliability and fast response time of photoelectric sensing make it a trusted choice for these critical safety functions.

When selecting a light limit switch for a specific application, several factors must be considered. The sensing distance required, the size and material of the target object, ambient light conditions, and the operating environment (presence of oil, coolant, or debris) all influence the choice. Modern switches come with features like adjustable sensitivity, time delays, and robust housing ratings (such as IP67 for dust and water resistance), allowing them to perform reliably in challenging conditions. Proper installation and alignment are also essential to ensure consistent and accurate detection, avoiding false triggers or missed signals that could disrupt the production line.

In conclusion, the light limit switch is far more than a simple sensor; it is a sophisticated component that enhances the intelligence, safety, and efficiency of automated systems. By providing precise, non-contact detection, it reduces mechanical stress, enables higher speeds, and supports the shift towards data-driven, predictive industrial operations. As automation continues to evolve, the role of reliable and versatile components like the light limit switch will only grow in importance, solidifying its position as an indispensable element in the landscape of modern industrial control.