Проверка

Проверка

Проверка

Проверка

Проверка

Проверка

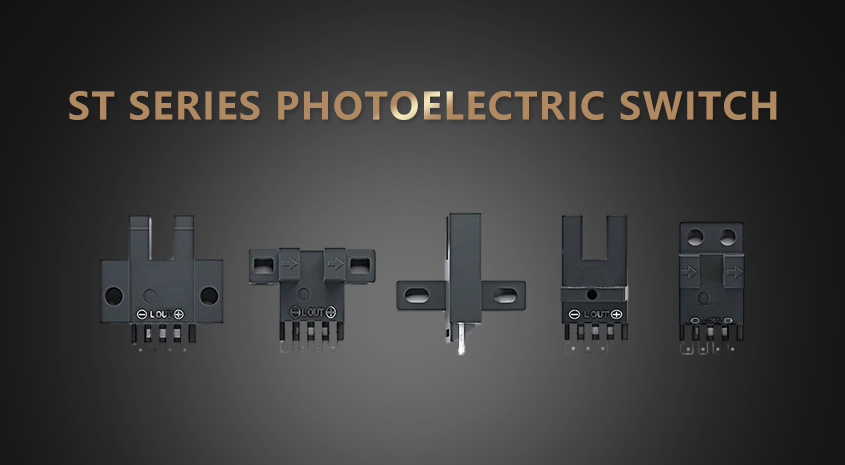

Unlocking Precision and Efficiency: The Role of Through Beam Photoelectric Sensors in Modern Automation In the fast-paced world of industrial automation, precision and reliability are non-negotiable. Whether it’s manufacturing, packaging, or logistics, the ability to detect objects accurately and efficiently can make or break a production line. Enter the Фотоэлектрический датчик с проникающим лучом, a cornerstone technology that has revolutionized object detection and counting in countless industries. This article delves into the workings, applications, and advantages of through beam photoelectric sensors, shedding light on why they are indispensable in modern automation.

А.Фотоэлектрический датчик с проникающим лучом, also known as a thru-beam sensor, is a type of photoelectric device designed to detect the presence or absence of objects. It consists of two separate components: a transmitter and a receiver. The transmitter emits a beam of light, typically infrared or visible light, which is then received by the receiver on the opposite side. When an object interrupts this beam, the sensor detects the change and triggers a response. Unlike other photoelectric sensors, such as retroreflective or diffuse-reflective types, through beam sensors rely on direct transmission of light. This design ensures high accuracy and long detection ranges, making them ideal for applications where precision is paramount.

The operation of a through beam photoelectric sensor is straightforward yet ingenious. Here’s a step-by-step breakdown:

Выбросы: The transmitter emits a focused beam of light.

Transmission: The beam travels through the air to the receiver.

Консьерж: The receiver continuously monitors the intensity of the incoming light.

Detection: When an object obstructs the beam, the receiver detects a drop in light intensity and sends a signal to the control system. This simple yet effective mechanism allows through beam sensors to detect objects of various shapes, sizes, and materials, including transparent or reflective surfaces.

Through beam photoelectric sensors offer several benefits that set them apart from other detection technologies:

High Accuracy: The direct transmission of light ensures minimal interference, resulting in precise object detection.

Long Detection Range: Through beam sensors can detect objects at distances ranging from a few centimeters to several meters, depending on the model.

Надежность: Their ability to function in harsh environments, such as extreme temperatures or dusty conditions, makes them highly dependable.

Многогранный.: These sensors can detect a wide range of materials, including glass, plastic, and metal.

Fast Response Time: With response times measured in milliseconds, through beam sensors are ideal for high-speed applications.

The versatility and reliability of through beam photoelectric sensors make them suitable for a wide array of industries. Here are some common applications:

Производство: In assembly lines, these sensors are used to detect the presence of components, ensuring seamless production processes.

Packaging: They play a crucial role in counting and sorting items during packaging, minimizing errors and improving efficiency.

Перевозка материалов: Through beam sensors are used to monitor conveyor belts, detecting jams or missing items.

Automotive: In the automotive industry, they ensure precise positioning of parts during assembly.

Продовольствие и напитки: These sensors are employed to detect bottles, cans, or packaging materials, ensuring hygiene and compliance with industry standards.

Selecting the appropriate through beam photoelectric sensor for your application requires careful consideration of several factors:

Detection Range: Ensure the sensor’s range matches the distance between the transmitter and receiver in your setup.

Beam Type: Depending on the application, you may need a visible beam for easy alignment or an invisible infrared beam for discreet operation.

Environmental Conditions: Consider factors such as temperature, humidity, and exposure to dust or chemicals.

Mounting Options: Choose a sensor with a mounting style that suits your setup, whether it’s bracket-mounted, threaded, or magnetic.

Тип экспорта: Determine whether you need a digital, analog, or relay output based on your control system’s requirements.

As technology advances, through beam photoelectric sensors continue to evolve, incorporating features that enhance their performance and usability. Some notable innovations include:

Laser-Based Sensors: These sensors use laser beams for even greater precision and longer detection ranges.

Smart Sensors: Equipped with advanced diagnostics and connectivity options, smart sensors provide real-time data and facilitate predictive maintenance.

Compact Designs: Modern sensors are increasingly compact, making them easier to integrate into space-constrained setups.

Energy Efficiency: Newer models consume less power, reducing operational costs and environmental impact.

As industries continue to embrace automation and Industry 4.0, the demand for reliable and efficient detection technologies like through beam photoelectric sensors is set to grow. Their ability to deliver high precision, versatility, and durability makes them a vital component in the automation ecosystem. In conclusion, through beam photoelectric sensors are more than just a detection tool; they are a catalyst for innovation and efficiency in modern industries. By understanding their capabilities and applications, businesses can unlock new levels of productivity and reliability in their operations.