Приближающийся датчик уровня

- time:2025-06-23 15:18:35

- Нажмите:0

Proximity Level Sensors: The Silent Sentinels of Modern Industrial Processes

Imagine a world without accurate level measurement. Fuel tanks run dry unexpectedly, vital chemical reactions halt mid-process, beverages overflow during bottling, and bulk storage silos either sit empty or suffer dangerous overfills. The invisible heartbeat of countless industrial and manufacturing operations relies on constantly knowing “how much is left.” This is where proximity level sensors step in – not just as tools, but as fundamental, reliable guardians ensuring smooth, safe, and efficient operations. These non-contact marvels have revolutionized how we monitor and control levels across a staggering array of applications.

At their essence, a Приближающийся датчик уровня is a device designed to detect the presence or absence of a target material (liquid, slurry, granulate, or powder) within a specific range – its “proximity” zone – without physical contact. This non-invasive nature is their defining superpower. Unlike traditional float switches or dipsticks, proximity sensors eliminate issues like material buildup, mechanical wear, contamination risk, and the need for direct immersion. They achieve this feat primarily through two dominant technologies:

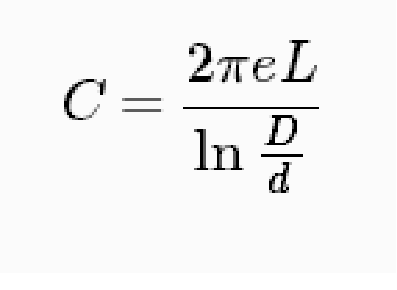

- Capacitive Proximity Sensors: These work by generating an electrostatic field. When the target material enters this field, it alters the sensor’s capacitance. Different materials have distinct dielectric constants. Capacitive sensors are exceptionally versatile, working with both conductive liquids (like water) and non-conductive materials (plastics, oils, grains, powders) by detecting changes in the field. This makes them a top choice for continuous level monitoring in diverse tanks, hoppers, and silos.

- Inductive Proximity Sensors: These generate an electromagnetic field. They are specifically designed to detect metallic targets or liquids with sufficient conductivity. As a conductive material enters the field, it induces eddy currents, which the sensor detects. Inductive proximity sensors excel in robust environments but are typically better suited for point-level detection (full/empty) rather than continuous measurement of non-metallic materials.

The compelling advantages of proximity level sensors are driving their widespread adoption:

- Non-contact Operation: This is paramount. It means no moving parts to jam, wear out, or require constant maintenance. There’s no risk of sensor corrosion or material contamination – crucial in food, beverage, and pharmaceutical industries where hygiene is non-negotiable. Robustness and longevity are inherent benefits.

- Многогранность: As mentioned, different types (capacitive vs. inductive) cater to a vast spectrum of materials, from aggressive chemicals and sticky syrups to free-flowing grains and powders unsuitable for contact sensors.

- Continuous Level Monitoring: Many proximity sensors, especially capacitive ones, provide continuous, real-time level feedback. This is invaluable for process control, ensuring optimal ingredient ratios, preventing overfills, and maintaining consistent feed rates crucial for process efficiency and product quality.

- Installation Flexibility & Simplicity: These sensors are typically mounted externally on the tank wall or threaded into a tank nozzle. This simplifies installation and maintenance significantly compared to intrusive probes or complex mechanical systems, reducing downtime and labor costs. Retrofitting existing systems is often straightforward.

- Robust Performance: Designed for industrial environments, proximity sensors boast high resistance to vibration, temperature fluctuations, pressure variations (within rated limits), and harsh chemical exposure. Many offer explosion-proof or intrinsically safe designs for hazardous areas.

Where are these “silent sentinels” making a significant impact?

- Chemical & Petrochemical: Monitoring aggressive acids, solvents, and fuels where contact sensors would degrade rapidly. Chemical resistance is critical.

- Food & Beverage: Ensuring ingredient levels in mixing tanks, detecting fill levels in bottles/cans without contamination, monitoring silos of grains or powders. Hygienic design is essential.

- Water & Wastewater: Controlling levels in treatment tanks, reservoirs, and sump wells. Corrosion resistance is often required.

- Pharmaceutical: Precise monitoring of sensitive ingredients and solutions under strict hygienic conditions. Accuracy and reliability are paramount.

- Bulk Solids Handling: Detecting levels of plastic pellets, grains, cement, flour, or minerals in silos and hoppers. They handle materials prone to bridging or buildup where contact sensors fail.

- Machine Tools & Hydraulics: Monitoring coolant levels in machining centers and hydraulic fluid reservoirs to prevent damage.

Choosing the Right Proximity Level Sensor:

Selecting the optimal sensor requires careful consideration of several factors:

- Material Type: Is it conductive, non-conductive, metallic, granular, or powdery? This primarily dictates the choice between capacitive and inductive technology. Capacitive sensors generally offer broader material compatibility.

- Tank/Vessel Construction: Material (metal, plastic), wall thickness, and potential lining can influence sensor performance, especially for capacitive models mounted externally. Sensor range needs to be sufficient.

- Environment: Consider temperature extremes, pressure, potential for explosive atmospheres (requiring ATEX/IECEx certification for intrinsically safe devices), humidity, and exposure to cleaning chemicals.

- Process Requirements: Is continuous level monitoring needed, or just high/low point detection? What level of accuracy and resolution is required?

- Output Signal: Common outputs include simple digital switches (P-N-P/N-P-N), analog signals (4-20mA, 0-10V), or digital protocols (IO-Link) for integration into control systems.

- Mounting Options: Threaded process connections (G 1⁄2”, NPT, etc.), flanges, or external clamp-on styles? Ensure compatibility with your vessel.

Investing in Efficiency and Reliability

Proximity level sensors are far more than just detection devices; they are foundational components for modern industrial automation, safety, and efficiency. Their non-contact principle eliminates a major source of failure inherent in mechanical solutions. Their robustness ensures reliable operation in demanding environments. Their versatility allows them to tackle level measurement challenges across countless industries. By providing accurate, continuous, or reliable point-level data, they empower process optimization, prevent costly spills and downtime, ensure product quality, and enhance overall operational safety. In the intricate dance of industrial processes, proximity level sensors are the dependable partners ensuring everything flows just right.