Проверка

Проверка

Проверка

Проверка

Проверка

Проверка

In the rapidly evolving landscape of industrial automation, the demand for precise, durable, and cost-effective sensing solutions is paramount. Among the core components driving this efficiency are photoelectric switches, devices that detect the presence, absence, or distance of objects using a light beam. A significant development in this field is the emergence of high-quality domestic 2-meter range photoelectric switches, which offer a compelling alternative for a wide array of applications.

Traditionally, long-range sensing was often dominated by imported brands. However, advancements in domestic manufacturing have led to the production of photoelectric switches with a reliable 2-meter (approx. 6.5 feet) sensing distance. This specific range is crucial for many industrial scenarios, such as monitoring conveyor belt gaps, detecting large objects on pallets, or controlling access in expansive warehouse areas. The ability to accurately sense at this distance without false triggers is a key performance indicator.

The core technology behind these 2M range switches typically involves a modulated infrared LED light source and a synchronized receiver. This modulation technique allows the sensor to distinguish its own light signal from ambient factory lighting, ensuring high immunity to optical interference. The housing of these domestic models is frequently constructed from robust engineering plastics or metals with an IP67 rating, making them resistant to dust, water jets, and the mechanical vibrations common in industrial environments. This ruggedness translates directly into reduced downtime and maintenance costs.

One of the most significant advantages of opting for a domestic 2M photoelectric switch is the optimization of the supply chain and cost structure. With local manufacturing and support, lead times are often shorter, and technical assistance is more readily accessible. This does not come at the expense of performance. Modern domestic sensors incorporate stable circuitry and precise optical components that deliver consistent response times and long-term operational stability, matching the reliability required for continuous production lines.

These switches come in various operational modes to suit different needs. The through-beam type, with separate emitter and receiver units, is ideal for achieving the full 2M range with high accuracy. The retro-reflective type, which uses a reflector, offers easier installation for similar distances. For applications requiring detection on one side only, diffuse or proximity sensors with a 2M range provide a versatile solution, though their effective distance can depend on the object's size, color, and reflectivity.

Integration into existing systems is straightforward. Most domestic 2M photoelectric switches offer both NPN and PNP output configurations, as well as NO (Normally Open) and NC (Normally Closed) contact options, ensuring compatibility with mainstream PLCs (Programmable Logic Controllers) and control systems from brands like Siemens, Allen-Bradley, or Mitsubishi. The wiring is typically simple, following international color-coding standards.

Application examples are vast. In packaging machinery, a 2M range sensor can detect when a stack of boxes reaches a certain height. In automotive assembly, it can verify the passage of vehicle chassis on an overhead line. In material handling, it safeguards automated guided vehicle (AGV) pathways by detecting obstacles at a safe distance. The robustness also makes them suitable for outdoor use in parking management systems or gate controls.

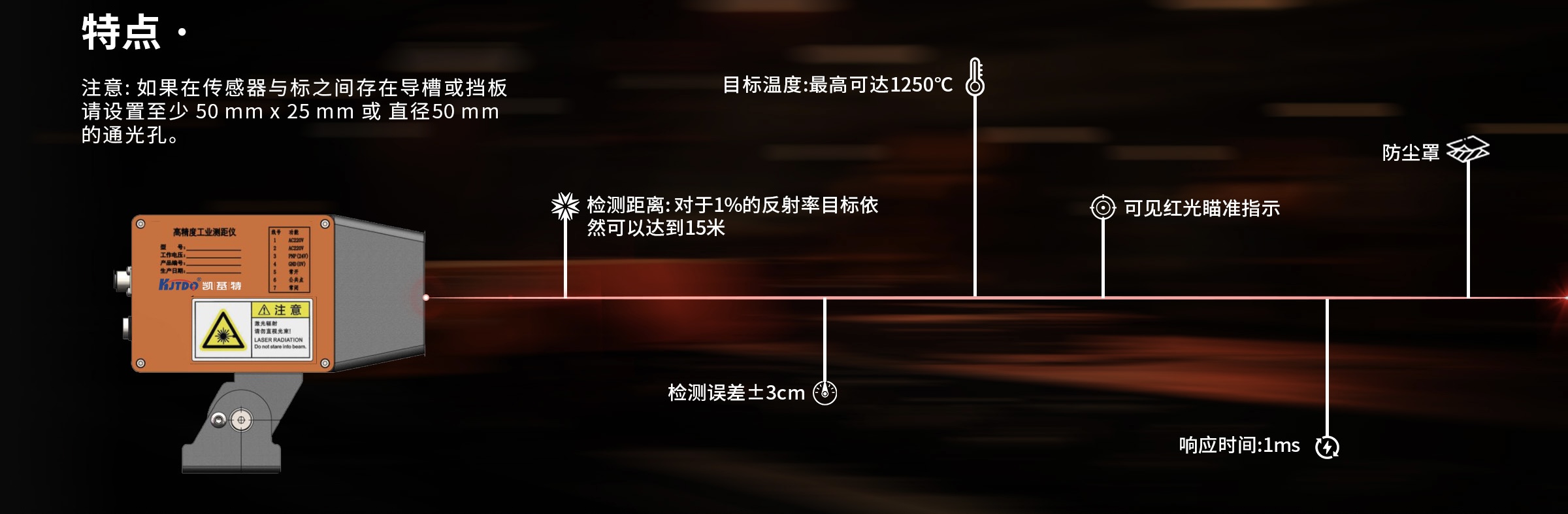

When selecting a domestic 2M photoelectric switch, key specifications to evaluate include the sensing range consistency, response speed (often in milliseconds), light source type, environmental ratings (IP, temperature range), and housing material. Reputable domestic suppliers provide detailed datasheets and application guides to assist in the correct selection for specific operational challenges.

In conclusion, the modern domestic 2-meter range photoelectric switch represents a mature, reliable, and economically sensible choice for industrial automation. It combines necessary performance for medium-range detection with the durability to withstand harsh conditions and the logistical benefits of local procurement. For engineers and system integrators looking to enhance line efficiency and reliability while controlling costs, these sensors present a formidable and practical solution, proving that domestic manufacturing can deliver core components that meet the rigorous demands of global industry standards.