Frequent cold air outbreaks, accompanied by continuous rain and snow, pose severe challenges to industrial sites in many areas, including low temperatures, condensation, and frost. The key to ensuring stable operation of equipment during these cold waves lies in the reliability of its core components.

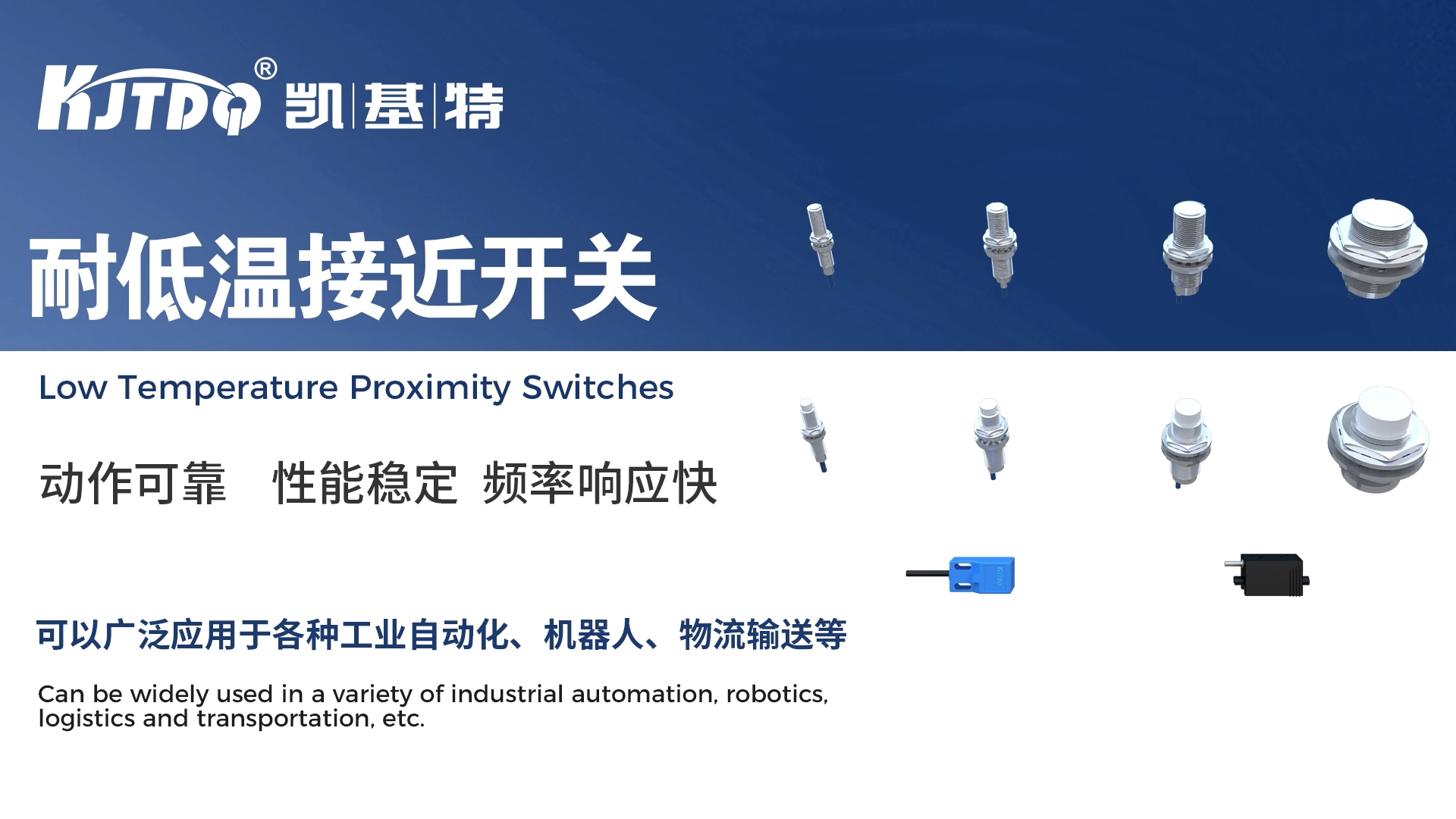

KJT Low Temperature Proximity Switch

Designed for extremely cold environments, it remains accurately online even at temperatures tens of degrees below zero, providing a solid barrier for continuous and safe production line operation.

01 Extreme Cold Adaptability · Designed for Low-Temperature Conditions

KJT low-temperature proximity switches, through structural reinforcement and upgraded cold-resistant materials, can operate stably in environments as low as -50℃.

Addressing common issues in traditional proximity switches at low temperatures, such as detection hysteresis, false triggering, and condensation damage, the product has undergone in-depth optimization in the following aspects:

Using low-temperature resistant electronic components and cable materials

Internal structure is reinforced against freezing to prevent performance degradation caused by cold contraction

Fully sealed encapsulation effectively inhibits condensation corrosion and internal moisture absorption

Performance remains consistently stable regardless of low-temperature shocks or long-term extreme cold exposure.

02 Precise Sensing & Rapid Response Even in Cold Weather

The low-temperature resistant proximity switch employs inductive or capacitive detection technology:

Metal object enters the sensing area

Oscillation frequency changes

Trigger signal output

Even at extremely low temperatures, its millisecond-level response speed and high repeatability remain unchanged, providing real-time and reliable data support for automated control.

Simultaneously, KJT uses a cold-resistant chip and anti-interference circuitry, maintaining stable output even in freezing conditions, unaffected by external factors such as temperature differences and electromagnetic noise.

03 High Protection · Born for Harsh Environments

Facing extreme scenarios such as ice, snow, frost, and damp cold, the product provides industrial-grade protection:

IP67 / IP68 high-level sealing

Moisture-resistant encapsulation design to prevent damage from low-temperature condensation

Abrasion-resistant and cold-resistant shell material, suitable for long-term outdoor use

Maintaining long lifespan even at low temperatures

Stability is reflected not only in testing performance but also in long-term durability in harsh environments.

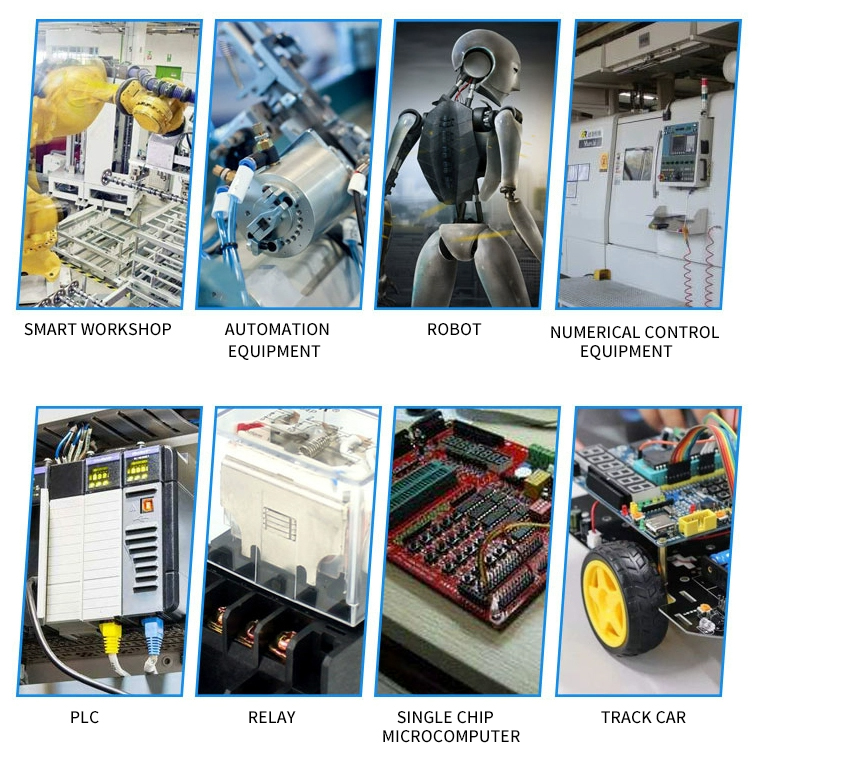

04 Application Scenarios • Covering All Low-Temperature Industrial Frontlines

KJT low-temperature proximity switches are widely used in:

Frozen Storage/Cold Chain Logistics

Used for material location detection, cargo identification, automated stacking, and unloading monitoring, enabling intelligent warehousing to operate efficiently in environments ranging from -20°C to 40°C.

Oil/Gas Low-Temperature Conditions

Suitable for valve, pipeline, and equipment detection in polar, deep-sea, and ice field environments, improving safety redundancy in the energy industry.

Polar Scientific Research Equipment

Ensuring the normal operation of outdoor scientific research equipment, unmanned observation points, and small machinery, coping with severe cold, snow, and extreme temperature differences between day and night.

More applications are extending to new energy, special equipment, and outdoor automation.

05 Moving Towards the Future: Intelligent Upgrades in Cryogenic Sensing

With the development of intelligent manufacturing, cryogenic proximity switches will play a more significant role in various scenarios.

In the future, KJT will continue to advance:

Integration of cryogenic sensors with IoT platforms

Remote monitoring and fault early warning

Wider temperature range, higher speed, and lower power consumption sensing technologies

Making equipment status more transparent, controllable, and efficient under extremely cold conditions.

KJT Low Temperature Proximity Switches

Stand accurate and reliable even in frigid environments, safeguarding every production line during cold waves.