Speed sensors are crucial "detection eyes" in fields such as automotive powertrains, rail transportation, power generation equipment, wind turbines, and industrial machinery.

How to choose the most suitable model from among so many options?

This selection guide makes the choice simpler.

I. Determining the Required Sensor Type

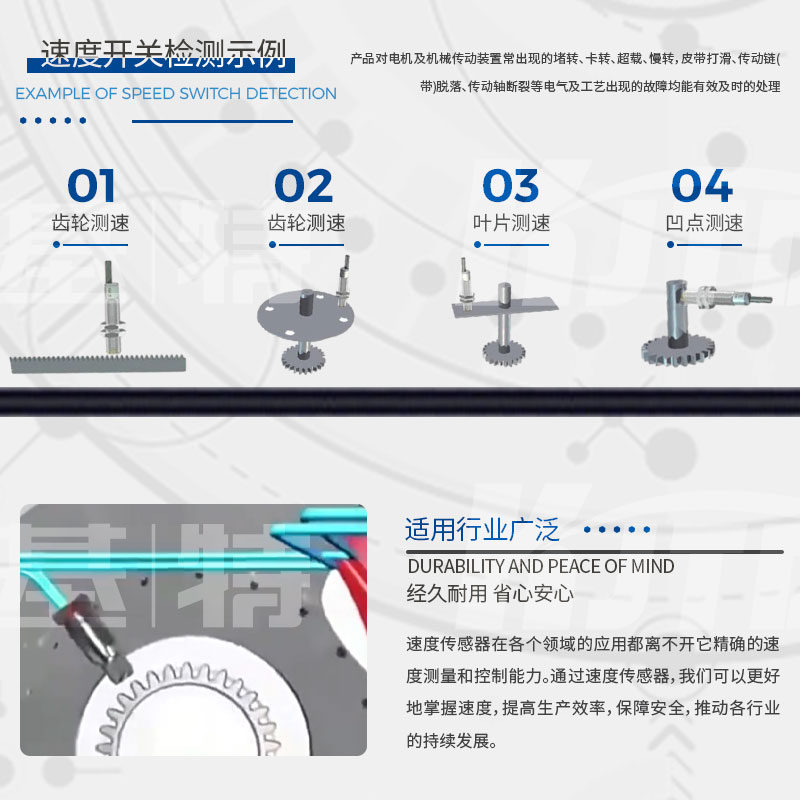

Different applications require different sensor principles. Common types include:

1. Eddy Current Velocity Sensor (Active/Passive)

Suitable for harsh environments such as high temperature, high pressure, and strong vibration.

Active: High precision, high stability

Passive: Simple structure, high durability

2. Hall Effect Velocity Sensor

Supports high-speed, high-frequency measurement

Widely used in automotive and industrial fields.

3. Variable Magnetoresistive (VR) Sensor

High sensitivity

Suitable for low-speed and precision applications.

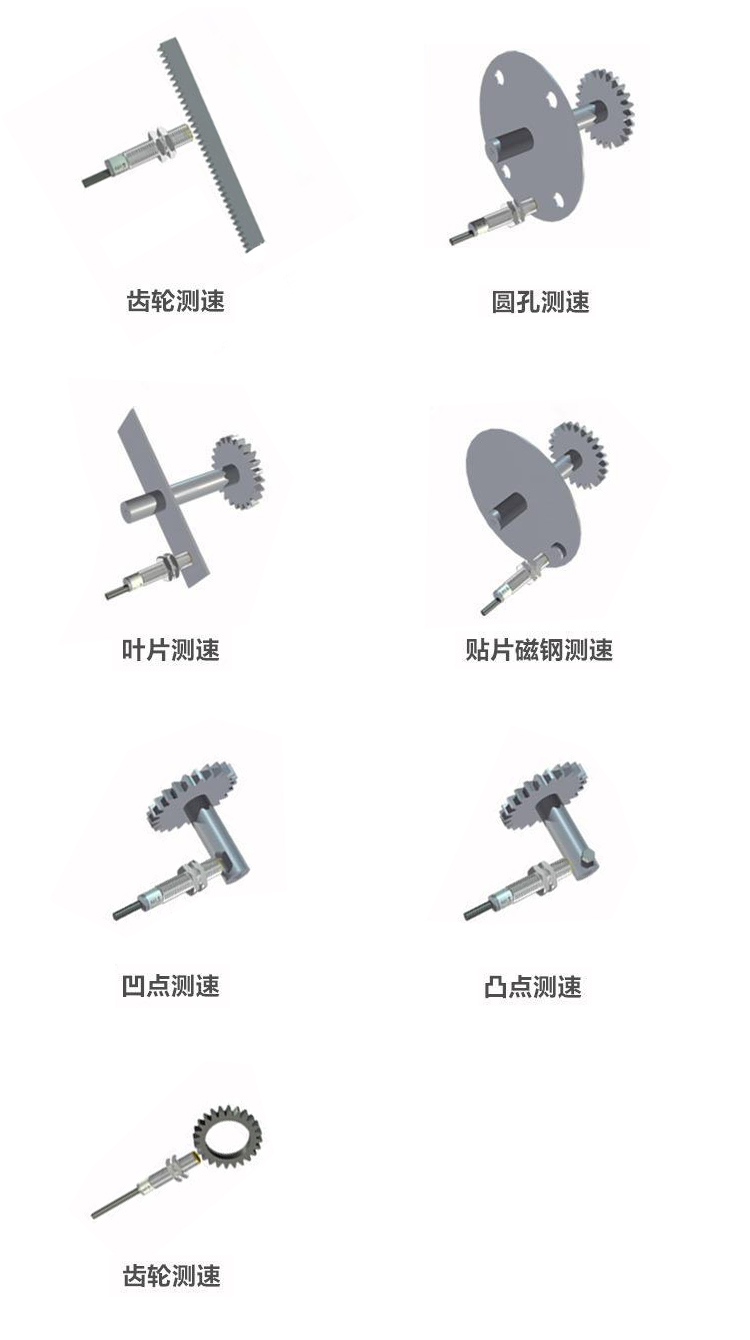

4. Gear Speed Sensor

Used with gears.

Stable signal, diverse output methods.

II. Key Confirmation Parameters

Whether a speed sensor is suitable depends mainly on the following points:

1. Measurement Range

Speed range (e.g., 0–10,000 RPM)

Can it identify gear tooth count and changes?

2. Measurement Accuracy

Does it meet system requirements (e.g., ±0.1%)?

Is the resolution high enough?

3. Output Signal Type

Select according to your control system:

Pulse/Frequency signal

0–10V / 4–20mA Analog

RS485 / CAN / Modbus Digital interface

4. Gear Parameters (e.g., for gear speed measurement)

Module, pitch, tooth width

Is the gear material a ferromagnetic metal?

Is the operation smooth?

III. Environmental Conditions Cannot Be Ignored

Speed sensors are often installed in high-temperature, high-vibration, high-humidity, or even hazardous areas. Environmental adaptability must be ensured:

Operating Temperature Range

Protection Rating (IP65 / IP67)

Vibration and Shock Resistance

Electromagnetic Interference Resistance (especially near motors and frequency converters)

IV. Confirm Installation and Power Supply Parameters in Advance

Installation Space and Dimensions

Probe Working Distance (e.g., 1–5mm)

Installation Method: Threaded / Flange

Power Supply Voltage: 12V / 24V

Power Consumption Meets System Requirements

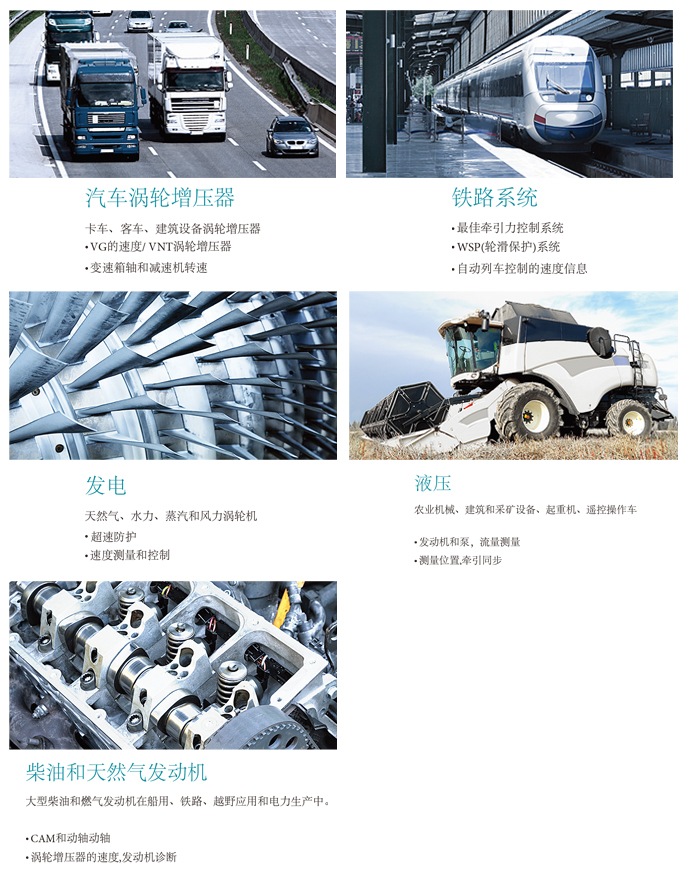

V. Recommended Sensor Types for Different Scenarios

Automotive & Commercial Vehicles: Hall Effect/Eddy Current Sensors

Railway: High-Reliability Active Systems

Power Generation Equipment: High-Temperature and Pressure Resistant Sensors

Wind Turbine Gearboxes: Gear + High-Frequency Speed Measurement Solution

Промышленное оборудование: VR or Hall Effect Sensors

Hazardous Environments: Explosion-Proof Speed Sensors

Summary: Six Key Selection Considerations

Type → Parameters → Output → Gear → Environment → Installation/Power Supply

Simply follow these six steps to quickly identify the most suitable speed sensor for your equipment.

As a professional sensor supplier, KJT offers a wide range of speed sensors and supports deep customization to create the perfect speed measurement solution for your equipment.

KJT, your sensor expert!