конденсаторный ограничитель

- time:2025-08-01 12:45:46

- Нажмите:0

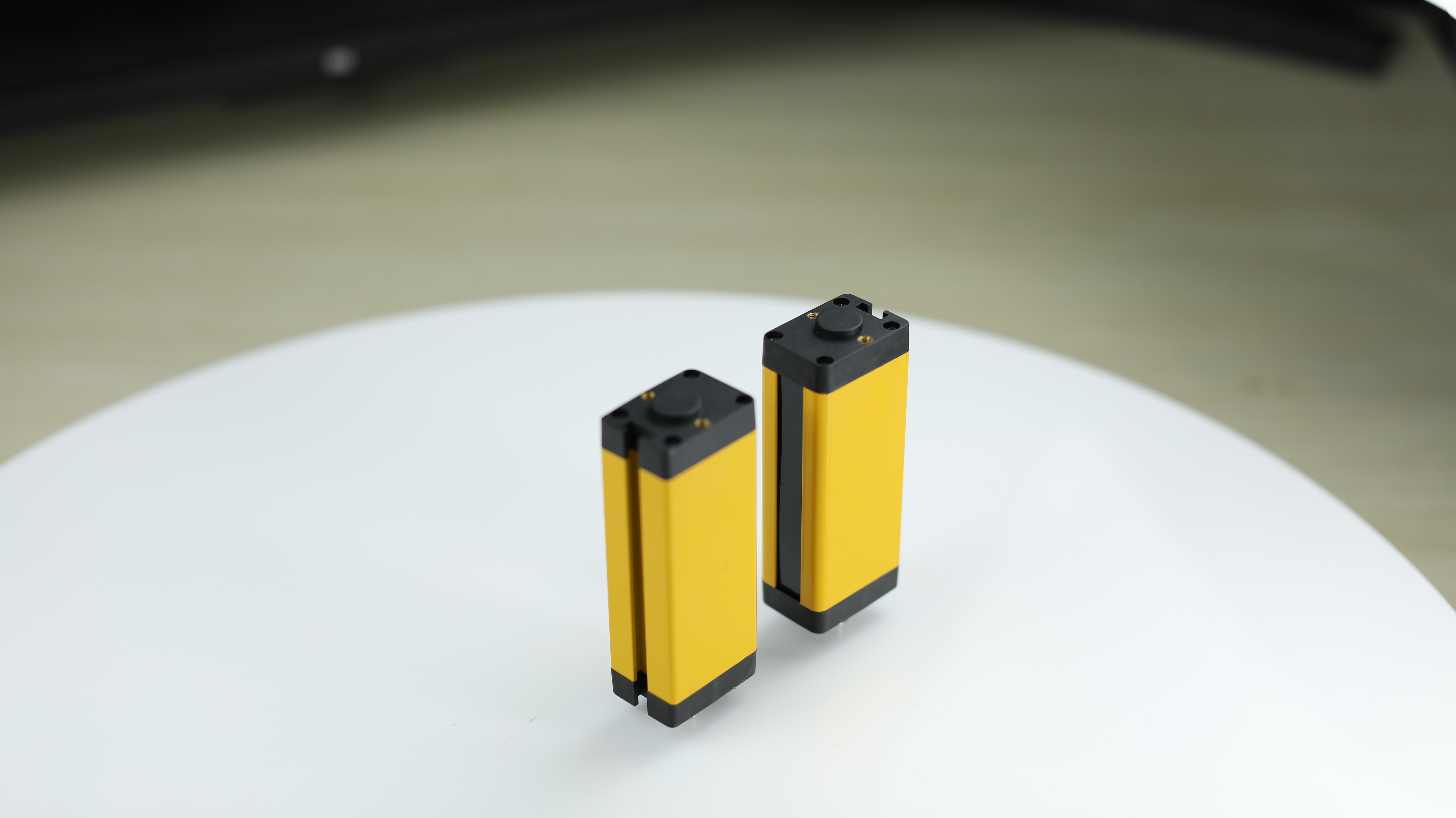

Capacitive Limit Switches: Revolutionizing Contactless Detection in Industrial Automation

In an industrial landscape demanding ever-greater precision, reliability, and hygiene, the unassuming capacitive limit switch has emerged as a silent powerhouse. Forget clunky mechanical arms and vulnerable sensors; this technology senses the world through subtle shifts in electrical fields, offering a paradigm shift in non-contact object detection. Understanding how capacitive switches work and where they excel is crucial for optimizing modern automation workflows.

At its core, a конденсаторный ограничитель functions by generating an electromagnetic field emanating from its sensing face. When any object – regardless of material – enters this field, it disrupts the capacitance (the ability to store an electrical charge) between the sensor’s electrodes. This subtle change in capacitance is the switch’s trigger mechanism. Importantly, the magnitude of this change depends significantly on the dielectric constant (εr) of the target object. Materials with higher dielectric constants (like water, metal, wood, or plastics) cause larger changes and are detected more easily at greater distances compared to materials with low dielectric constants (like air or certain foams).

This fundamental principle unlocks several distinct advantages over traditional sensing technologies:

- True Contactless Operation: The critical benefit is the complete absence of physical contact. Unlike mechanical limit switches prone to wear, breakage, and misalignment, capacitive sensors detect objects without touching them. This translates directly to dramatically reduced maintenance requirements and significantly longer operational lifespans. Friction, a major cause of failure in mechanical counterparts, is entirely eliminated.

- Material Agnosticism (Within Reason): While detection range varies, capacitive switches reliably sense a vast array of materials: metals, plastics, glass, wood, liquids, powders, and granules. This versatility makes them invaluable in complex applications where target materials might vary. Unlike inductive sensors, which only detect metals, capacitive sensors offer broader applicability.

- Immunity to Contaminants: Dust, dirt, oil, and moisture typically wreak havoc on optical sensors and can jam mechanical mechanisms. Capacitive sensors, however, are largely unaffected by such environmental contaminants. They perform reliably in harsh conditions like foundries, woodshops, food processing plants, and dusty outdoor settings, where optical sensors might fail due to obscured lenses or mechanical switches gum up. Many models feature robust IP67 or IP69K ratings for washdown environments.

- Seeing Through Walls: A unique capability is the power to detect objects through non-metallic barriers. Capacitive sensors can “sense” levels of liquids inside plastic or glass containers, detect objects through thin walls, or even monitor fill levels in sealed tanks constructed from materials like fiberglass or PVC. This non-invasive capability is impossible for mechanical, inductive, or most optical sensors.

- Position Insensitivity: Unlike photoelectric sensors that require precise alignment or mechanical switches needing direct contact, capacitive sensors generally do not require precise orientation relative to the target. The sensing field surrounds the active area, offering more flexibility in mounting.

- Sensitivity Adjustment: Most capacitive limit switches feature a potentiometer or teach-in function, allowing operators to fine-tune the sensing range and optimize performance for the specific target material and application, minimizing false triggers.

Key Applications Where Capacitive Limit Switches Shine

The unique strengths of capacitive sensing make them the ideal choice for numerous demanding industrial tasks:

- Level Detection: Monitoring fluid levels in tanks (water, oil, chemicals, food products) through tank walls (glass, plastic, fiberglass). Detecting granular or powdered material levels in hoppers and silos, even in dusty conditions.

- Presence/Absence Verification: Confirming the presence of bottles/caps on a filling line (glass or plastic), detecting labels on packages, verifying the presence of workpieces on a conveyor (wood, plastic, metal), or ensuring a part is seated correctly in a fixture.

- Hygienic Environments: Food & beverage and pharmaceutical industries demand high hygiene standards. Sealed capacitive sensors (often with FDA-compliant materials) excel here, detecting product or packaging through barriers without crevices where bacteria could grow, and easily surviving rigorous CIP (Clean-in-Place) or SIP (Sterilize-in-Place) processes. Contamination immunity is paramount.

- Detection Through Barriers: As mentioned, sensing objects on the other side of thin non-metallic walls, doors, or covers – a task impossible for most other sensor types.

- Aggressive/Dirty Environments: Foundries (detecting sand molds or core boxes), woodworking (sawdust immunity for detecting boards or panels), recycling plants (detecting mixed material streams), and construction equipment.

Selecting the Right Capacitive Limit Switch: Factors to Consider

While incredibly versatile, selecting the optimal capacitive sensor requires careful consideration:

- Target Material: Identify the primary material(s) to be detected. Remember that materials with high dielectric constants (water, metals) are detected at the longest nominal range. Low-dielectric materials (foam, dry wood) require closer proximity or sensors designed for longer ranges.

- Sensing Distance: Clearly define the required detection distance. Nominal ranges vary significantly between models. Account for any barriers the field must penetrate. Always consult datasheets and apply generous safety factors – effective range can be halved or more when sensing through walls.

- Barrier Material & Thickness: If sensing through a container wall, know the exact material type and thickness. The switch must generate a field strong enough to penetrate the barrier and still detect the target material change effectively. Plastic walls significantly reduce the usable sensing range.

- Environmental Conditions: Consider temperature extremes, potential chemical exposure, humidity, pressure (for pressurized tanks), and the required Ingress Protection (IP) rating. Harsh environments demand robust construction.

- Output Type & Wiring: Specify the required electrical output (PNP/NPN transistor, NO/NC, Analog), voltage rating, and connection type (cable or connector).

- Mounting & Form Factor: Cylindrical (M8, M12, M18, M30), rectangular, or block-style sensors? Space constraints often dictate the physical size and shape.

Beyond the Basics: Shielding and Other Considerations

Most capacitive sensors incorporate a Faraday shield (a grounded ring around the active electrode). This focuses the sensing field forward, reducing the sensor’s side sensitivity and preventing unintended triggering from nearby grounded objects like metal brackets or machine frames. Understanding shielding helps prevent installation headaches.

The evolution of the capacitive limit switch represents a significant leap forward in sensing technology. By harnessing the principles of capacitance, these switches deliver unmatched versatility, robustness, and contactless operation in scenarios where mechanical switches falter, inductive sensors are blind, and optical sensors struggle with contamination. From ensuring precise fill levels in sparkling water bottles to verifying the presence of delicate wooden components in a dusty workshop, capacitive sensors provide a reliable, low-maintenance solution. Integrating this powerful sensing technology unlocks new levels of efficiency and reliability, solidifying its role as an indispensable component in the intelligent factory of today and tomorrow.