Датчик приближения батареи

- time:2025-07-05 01:42:32

- Нажмите:0

Unlock Wireless Freedom: The Ultimate Guide to Battery-Powered Proximity Sensors

Imagine installing a critical safety sensor on a moving machine part without the hassle and cost of running wires. Picture adding occupancy detection to a historic building without tearing into walls. Envision monitoring remote assets in a field for months without needing grid power. This is the transformative potential unlocked by battery-powered proximity sensors. These ingenious devices combine the non-contact detection capabilities of traditional proximity sensors with the unparalleled flexibility and independence of battery operation, revolutionizing how we interact with and monitor the physical world.

Beyond the Wire: Defining Battery-Power Proximity Sensing

At its core, a battery-powered proximity sensor performs the same fundamental task as its wired counterpart: detecting the presence, absence, or position of an object without physical contact. It achieves this using various technologies – primarily inductive (for metals), capacitive (for various materials including liquids), or photoelectric (using light beams). However, the defining characteristic is its self-contained power source – typically a battery pack – which eliminates the need for a continuous wired connection to a mains power supply or a central control system. This fundamental shift enables deployment scenarios previously impractical or prohibitively expensive.

- Inductive Sensors: Detect metallic objects via electromagnetic fields. Battery-powered versions are crucial for mobile metal parts or harsh environments where wiring is fragile.

- Capacitive Sensors: Sense materials like plastic, wood, liquids, or granular substances by measuring changes in capacitance. Battery operation allows embedding them within non-metallic containers or structures.

- Photoelectric Sensors: Use light beams (visible, infrared, laser) to detect objects breaking the beam or reflecting light back. Battery power enables truly wireless light curtains or presence detection over distances.

The Driving Force: Why Choose Battery Power?

The advantages of battery-operated proximity detectors extend far beyond simply avoiding wires:

- Unparalleled Installation Flexibility & Cost Savings: Eliminate the significant labor and material costs associated with running conduit and cables, especially over long distances, through walls, across moving machinery, or in hard-to-reach locations. Installation becomes significantly faster and cheaper.

- Simplified Deployment: Truly plug-and-play installation. Mount the sensor, configure it if needed (often via simple dip-switches or Bluetooth Low Energy - BLE), and it’s operational. This reduces setup complexity and technician time dramatically.

- Enhanced Mobility: Perfect for monitoring moving equipment, vehicles, robotic arms, or temporary setups where trailing wires are unsafe or impractical. The sensor moves freely with its target.

- Accessibility in Remote Locations: Monitor assets or environmental conditions in fields, forests, pipelines, or unpowered structures (like bridges, silos, or remote sheds) without needing grid access or complex solar setups.

- Preservation of Existing Structures: Install sensors in historic buildings, finished spaces, or sensitive environments without disruptive wiring work. Maintain aesthetics and structural integrity.

- Повышение безопасности: Reduce risks associated with running wires near high-voltage equipment, flammable materials, or wet areas. Fewer wires also mean fewer potential failure points and trip hazards.

- Scalability: Adding more sensors is often as simple as mounting and configuring a new unit, without complex rewiring or control panel expansions.

Powering the Future: Batteries and Energy Management

The longevity of a wireless proximity sensor hinges critically on efficient power management:

- Battery Types: Commonly use standard industrial-grade lithium (Li-SOCl2, Li-MnO2) or alkaline batteries, chosen for capacity, temperature tolerance, and long shelf life. Some specialized sensors may feature rechargeable options (Li-ion/Li-Po).

- Low-Power Design: Modern sensors are engineered for minimal power consumption. Key strategies include:

- Ultra-Low Standby Current: Drawing microamps when not actively sensing.

- Smart Triggering: Waking only when potential target movement is detected (e.g., using a passive infrared - PIR - wake-up).

- Optimized Sensing Cycles: Taking measurements only as frequently as necessary.

- Efficient Communication: Utilizing low-power protocols like BLE for configuration or data transmission only when needed.

- Energy Harvesting (Emerging Trend): Some advanced sensors augment batteries by scavenging energy from their environment (ambient light, vibration, temperature differentials), dramatically extending operational life or even enabling battery-free operation in the future.

- Battery Life Indicators: Many units feature low-battery warning signals (LEDs, wireless alerts) or sophisticated state-of-health monitoring over wireless networks.

Where Wireless Detection Shines: Key Applications

The versatility of battery proximity sensors makes them invaluable across numerous sectors:

- Industrial Automation & Machinery: Monitoring position of mobile components on automated guided vehicles (AGVs), robots, or conveyor sections. Safety interlocks on movable guards or access doors without wiring constraints.

- Asset Tracking & Logistics: Detecting the presence/absence of pallets, containers, or tools in warehouses or yards. Monitoring door/window status (open/closed) on trailers or shipping containers.

- Building Automation (BMS): Occupancy detection for lighting/HVAC control in retrofit projects or open-plan offices. Tamper detection on access panels or windows. Level sensing in non-powered tanks.

- Agriculture & Environment: Monitoring gate positions on vast farmland. Sensing water levels in remote tanks. Detecting equipment presence in fields. Environmental sensing networks.

- Smart Cities & Infrastructure: Monitoring parking space occupancy. Detecting waste bin fill levels. Monitoring vibration or displacement on structures like bridges.

- Consumer & IoT: Smart home applications (cupboard/door sensors), interactive installations, DIY projects, and portable equipment requiring presence detection.

Selecting Your Ideal Battery Sensor: Key Considerations

Choosing the right battery-powered proximity detector requires evaluating several factors:

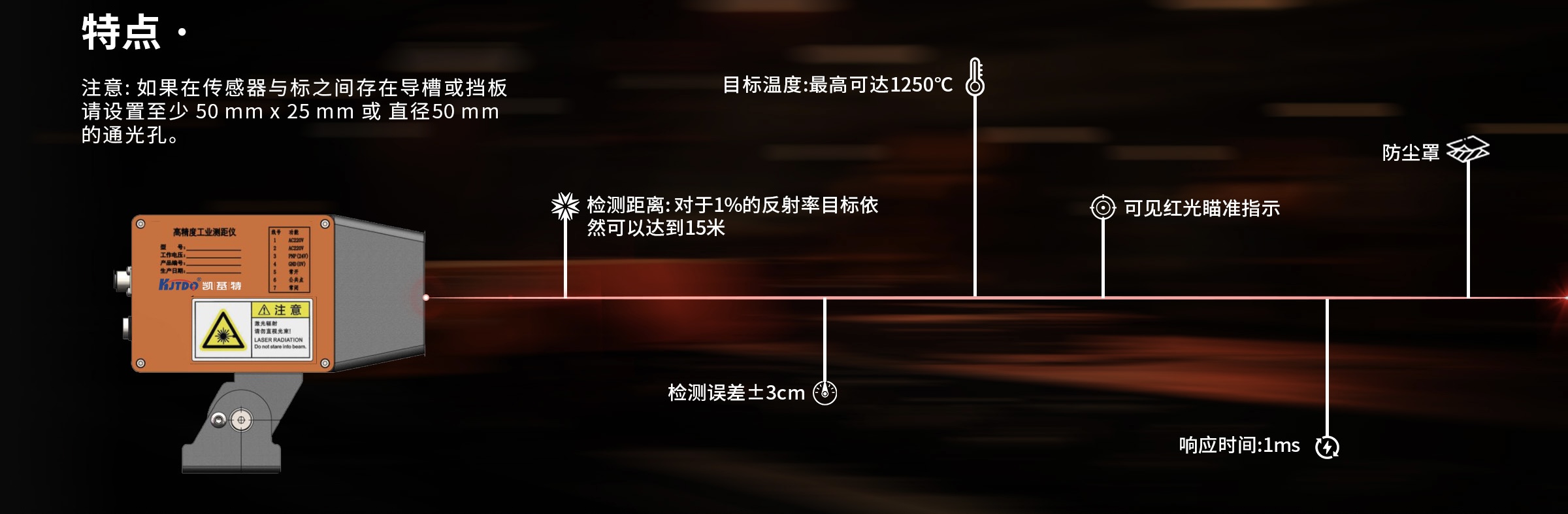

- Sensing Technology: Inductive (Metals only), Capacitive (Metals, liquids, powders, plastics), or Photoelectric (Beam break/reflectance for diverse objects)? Match to your target material and environment.

- Detection Range: What distance do you need to reliably detect the object? Ensure the sensor’s specified range meets or exceeds this with a safety margin.

- Operating Environment: Consider temperature extremes, humidity, potential for dust/dirt/water ingress (IP rating: IP67 is common for industrial use), chemicals, or explosive atmospheres (ATEX/IECEx if needed). Vibration resistance is also crucial.

- Output Signal: What action triggers the detection? Simple discrete switch (NPN/PNP) outputs are common. Some sensors offer configurable digital outputs, analog outputs, or wireless communication (LoRaWAN, Sigfox, NB-IoT, BLE, Wi-Fi) for integration into IoT platforms.

- Required Battery Life: Calculate based on sensing duty cycle, transmission frequency (if wireless), and environmental conditions. Aim for a life exceeding your practical maintenance interval. Models with very low power consumption can last 5-10 years.

- Configuration & Diagnostics: Does it require simple adjustments via buttons/dip-switches, or offer convenient wireless configuration (BLE smartphone app)? Are diagnostic LEDs or remote status alerts important?

- Physical Size & Mounting: Ensure the sensor fits the available space and suitable mounting options (brackets, threaded barrels, magnets) are available.

Ensuring Long-Term Reliability: Maintenance Best Practices

Maximizing the value of your wireless proximity sensor investment involves proactive maintenance:

- Battery Management: Establish a schedule for checking and replacing batteries based on manufacturer estimates and observed usage. Utilize low-battery alerts. Choose high-quality, temperature-appropriate batteries. For critical applications, consider staggered replacement programs.

- Environmental Vigilance: Periodically inspect the sensor for physical damage, excessive dirt/dust buildup (clean carefully if needed), moisture intrusion, or corrosion, especially in harsh settings.

- Functional Testing: Regularly verify that the sensor is detecting targets correctly