Датчик приближения 4мм

- time:2025-06-14 01:54:40

- Нажмите:0

The Mighty Miniature: Why 4mm Proximity Sensors Are Precision Powerhouses in Modern Automation

Imagine a world where machines operate blindly, unable to sense the presence of components whizzing by on a high-speed assembly line. Collisions would be frequent, positioning errors rampant, and quality control impossible. Thankfully, the unassuming proximity sensor, particularly models with a 4mm sensing range, acts as the essential “eyes” for countless automated systems. These compact marvels deliver unmatched precision in short-range detection, proving that great sensitivity often comes in small packages. This article delves into the world of the Датчик приближения 4мм, exploring its workings, critical applications, and why it’s a cornerstone of reliable industrial automation.

At its core, a proximity sensor detects the physical presence of an object without any physical contact – hence the term non-contact sensing. While various technologies exist (inductive, capacitive, photoelectric), inductive proximity sensors are exceptionally common in industrial settings, especially those specified with a 4mm range. These sensors generate an electromagnetic field around their active face. When a metallic target enters this field – specifically, within approximately 4 мм of the sensor face – it induces eddy currents within the target, causing a detectable change in the sensor’s internal oscillation circuit. This change triggers the sensor’s electronic switch.

The magic of a Датчик приближения 4мм lies in its compact size combined with this defined short-range detection capability. This specific range is meticulously chosen for applications where:

- Space is Tight: Machinery designs are increasingly dense, demanding components with minimal footprint. A Датчик приближения 4мм fits into cramped locations where larger sensors simply cannot.

- Precision is Paramount: Detecting objects very close to the sensor face prevents accidental triggering by background objects or passing machinery components, ensuring reliable object presence confirmation at a precise location.

- Small Targets Matter: From tiny screws and washers to fine electronic components, the 4mm sensing range is ideal for reliably detecting diminutive parts on vibratory feeders, pick-and-place machines, or assembly stations.

These attributes make the Датчик приближения 4мм indispensable across numerous industries. Let’s explore key applications:

- Micro-Assembly & Electronics: Verifying the precise placement of miniature components on circuit boards (PCBs), detecting pins in connectors, or confirming the presence of small screws during automated assembly. Failure here could lead to costly defects or product malfunctions.

- High-Speed Packaging: Monitoring the position of small product containers, detecting caps on bottles, confirming folded flaps on cartons, or checking for labels on blister packs – all at blistering speeds where reliability and precision are non-negotiable.

- Robotics & CNC Machinery: Providing end-of-arm tooling (EoAT) verification (e.g., confirming a gripper holds a part), acting as homing or limit switches within compact robot joints, or detecting tool presence/tool breakage in CNC spindles.

- Automotive Manufacturing: Counting small parts like bolts fed into machines, confirming seat belt buckle presence, detecting gear teeth position for indexing, or ensuring the correct insertion of plugs and sensors into engine blocks. Maintaining high throughput while ensuring component presence is critical.

- Safety & Positioning: Acting as non-contact position feedback in valve actuators where space is limited, confirming door closure on equipment, or detecting the position of machine guards.

Beyond the “4mm”: Key Features and Benefits

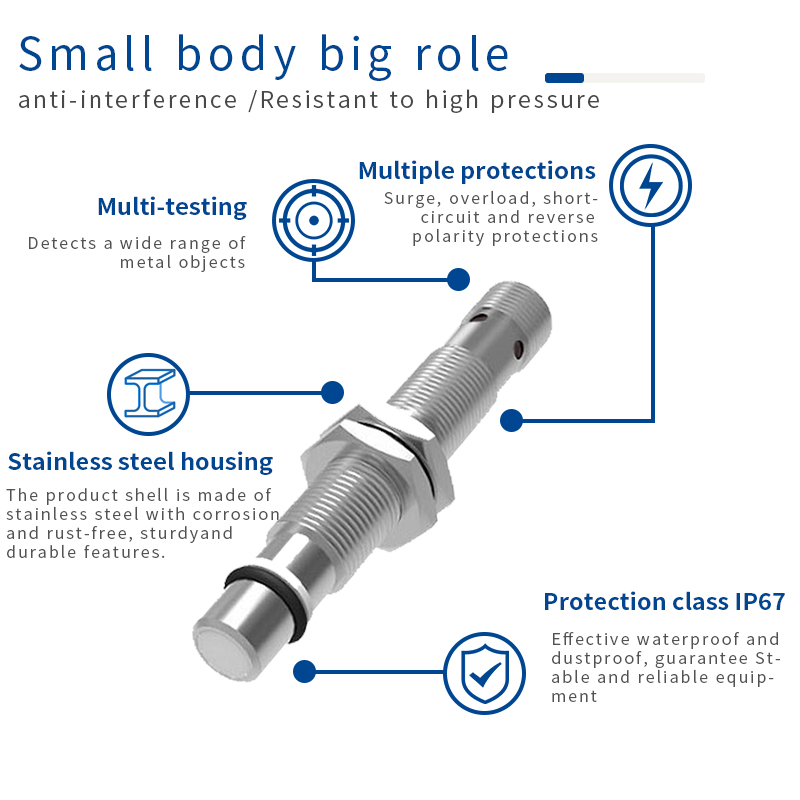

While the sensing distance defines its niche, a high-quality Датчик приближения 4мм offers more:

- Non-Contact Operation: Eliminates mechanical wear and tear, leading to long operational life and minimal maintenance, a significant advantage over mechanical switches.

- High Switching Frequency: Capable of detecting rapidly moving objects, essential for modern high-speed automation.

- Resilience: Typically housed in rugged materials like nickel-plated brass or stainless steel, many boast МП67 or higher ratings, making them resistant to dust, coolants, oils, and washdown environments.

- Simple Integration: Common NPN или PNP output configurations (sourcing or sinking) and various connection types (cable, connector, M8/M12) allow for straightforward connection to most programmable logic controllers (PLCs) and control systems.

- Энергоэффективность: Modern sensors consume very little power, contributing to sustainable operations.

Choosing the Right 4mm Proximity Sensor: Several factors influence the optimal choice:

- Target Material: Inductive sensors excel with ferrous and non-ferrous metals. For non-metallic targets (plastic, wood, liquid), a конденсаторный датчик приближения with a similar range might be necessary.

- Output Type: NPN vs. PNP depends on the control system’s input requirements (sinking vs. sourcing).

- Build Material & IP Rating: Crucial for environmental conditions (chemicals, washdown, temperature extremes). Stainless steel housings and high IP ratings are vital for harsh industrial settings.

- Electrical Connection: Pre-cabled or connector type (M8, M12) affects ease of installation and maintenance.

- Approval Ratings: Specific industries (food & beverage, hazardous locations) may require certifications like UL, ATEX, or IECEx.

The Датчик приближения 4мм is far more than just a component; it’s a critical enabler of precision and reliability in a world demanding ever-smaller, faster, and smarter manufacturing. Its compact size, defined short-range accuracy, and robust non-contact operation make it uniquely suited for applications where space is constrained, targets are small, and dependable detection is paramount. From ensuring the tiniest electronic component is present to safeguarding high-speed packaging lines, this miniature powerhouse plays a mega role in the seamless and efficient operation of modern industry. Understanding its capabilities and specifications is key to unlocking its full potential in optimizing automated processes.